Axial III Plasma Spray System

Flexibility, Reliability, Robustness

Mettech's Axial III Plasma Spray System is a robust and highly reproducible industrial piece of equipment that can apply almost any coating. Axially injected feedstock of any kind ensures consistent heat treatment of all materials, which leads to superior deposition efficiencies and reproducibility of coatings. High particle velocities approaching those previously possible only with HVOF technology add a whole new spectrum of materials and coatings achievable with Axial III.

Control of Axial III deposition process is done by two computer based modules, one designed to control Axial III plasma process, the other to enable User Interface (UI). Due to modular design of control hardware and open architecture of control software Axial III can be easily integrated to almost any spray infrastructure to form fully automated spray facility.

Standard Axial III System Components

- Axial III plasma torch

- plasma power supplies

- computer-based control module

- computer-based user interface

- customized interconnection bundle for full integration

- on-site integration and system startup

- starting plasma parameters for coating(s) of interest

Optional Axial III System Components

- ancillary third-party plasma spray equipment including feeders, robots, water chillers, etc.

- integration of customer infrastructure and equipment with Axial III computer control

- integration of conventional, third-party spray torches with Axial III computer control

- Mettech assistance in development of coating applications

Axial III Applications Highlights

- wear protection (abrasion, adhesion, fretting, erosion, cavitation)

- thermal barriers

- printing rollers

- clearance control (abradable coatings)

- material buildup and component repair

- corrosion /oxidation protection

- electrical and electronic components

- spray forming

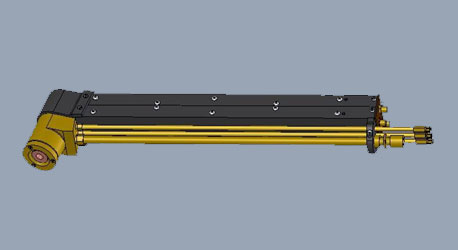

Axial III Plasma Spray Torch

The Axial III Torch is a patented, three cathode plasma torch with axial injection of feedstock. Three plasma jets generated by three independent DC (direct current) arcs converge into one unified plasma plume inside the torch. The feedstock is injected into the centre of unified plasma jet along the axis of its flow. Consequently all of the feedstock can be fully entrapped inside and melted within the plasma before being projected onto the coated surface. This, in turn, results in high Deposition Efficiencies (DEs)and ability to use high feed rates.

Thanks to axial injection, three-plasma-jet design, and outlet nozzle geometry, particle velocities can be tightly controlled in a very wide range. The particle velocity range spans from lows comparable to conventional equipment to highs at HVOF levels. The high velocity feature allows Axial III to be used for deposition of coatings traditionally achievable only with HVOF systems but at much higher deposition and spray rates.

Axial III Torch comes in two shapes, designed for spraying external or internal surfaces of hollow parts. Both torches have identical internal geometry of electrodes and plasma channels and consequently can produce identical coatings at same plasma parameters.

In-line Axial III |

ID Axial III ID Axial III |

Torch Specifications - Standard

- plasma jets: three converging

- plasma chemistry: Ar, N2, H2 (He)

- plasma flow: 100-300 slm

- power range: 30-150 kW

- arc current: 100-300 amps/jet

- feedstock injection: axial with plasma flow

- spray distance: 50-250 mm

Torch Specifications - ID

- Plasma jets: three converging

- Plasma chemistry: Ar, N2, H2 (He)

- Plasma flow: 100-250 slm

- Power range: 30-125 kW

- Arc current: 100-250 amps/jet

- Feedstock injection: axial with plasma flow

- Spray distance: 50-250 mm

- ID capacity: > 330 mm

English:

English:  Japanese:

Japanese:  Hindi:

Hindi:  Korean:

Korean: