Axial III Suspension Plasma Spray

Supremacy in Sub-Micron Spraying

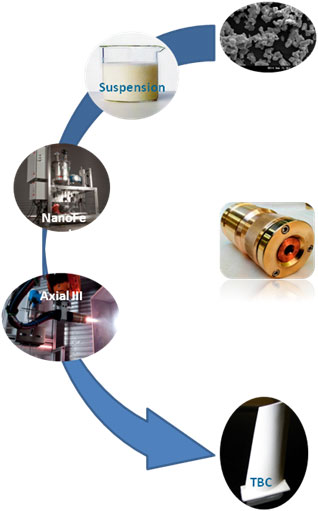

Mettech's NanoFeed line of liquid and suspension feeders for spray industry has been developed to enable delivery of submicron powders to thermal spray torches. The NanoFeed delivery systems provide the only efficient way to convey ultrafine powders to the torch. The powders are homogenously suspended in an easy to transport liquid medium, which is then delivered to the torch with a precisely controlled rate. Nanofeed units come either standalone or integrated with spray system. Integration with Axial III is seamless.

Integration of Mettech's Axial III plasma system with NanoFeed suspension delivery device resulted in new technology, Axial III Suspension Plasma Spray (SPS). Axial III SPS is capable of producing large variety of unique nanostructured coatings with characteristics completely different from those deposited from powders of the same chemistry.

Uniqueness of Axial III SPS derives from its axial injection principle. This form of injection is the only one which allows nano-size (<1µm) particles and droplets entering the plasma plume.

One family of coatings where Axial III SPS has proven to be a viable alternative to existing technologies are thermal barrier coatings (TBCs) for high temperature turbine components.

High end TBCs are generally produced by slow and very expensive vacuum process called electron beam physical vapor deposition (EB-PVD). Low end TBCs are thermally sprayed in atmosphere in the process called Atmospheric Plasma Spraying (APS).

Axial III SPS produces TBCs with equivalent properties to that of EB-PVD coatings, but at much lower operating and capital costs, whereas Axial III APS can economically do the low end ones.

Other areas of interest that can benefit from Axial III SPS are nano-ceramics and nano-cermets for power generation, fuel cell, and electronic industries.

Axial III SPS Process Axial III SPS Process |

Turbine blade before and after Axial III SPS deposition of TBC Turbine blade before and after Axial III SPS deposition of TBC |